Embracing the Future with Innovation and Printed Pasta

26 January 2018Blu1877 takes on technology and imagination in its development of 3D printed pasta.

By Lisa Parrish, GMC Editor and Jacqueline Delgado, business development at Blu1877

The process of mixing flour with either water or eggs and extruding dough through a die has been around for hundreds, even thousands of years with little change. However, technology marches on and in the space of a few years the process is being transformed into something a chef would never have thought possible just five years ago. This pasta design innovation is thanks to the 3D printer and its ability to extrude dough in intricate patterns limited only by imagination and gravity.

The process of mixing flour with either water or eggs and extruding dough through a die has been around for hundreds, even thousands of years with little change. However, technology marches on and in the space of a few years the process is being transformed into something a chef would never have thought possible just five years ago. This pasta design innovation is thanks to the 3D printer and its ability to extrude dough in intricate patterns limited only by imagination and gravity.

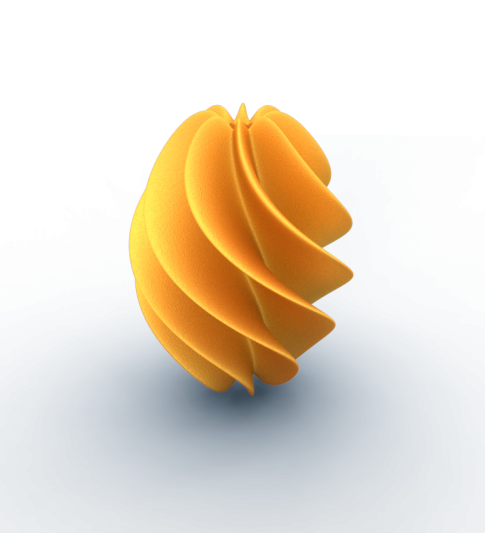

BluRhapsody, a brand created by Blu1877, an innovation company under the Barilla umbrella, is leading the drive to create pasta designs that surprise both the eye and palate. BluRhapsody’s prototype 3D printer utilizes a pasta design concept created in a computer-aided-design (CAD) program. From there the printer is loaded with dough-filled cartridges that extrude tiny lines in concentric layers at ambient temperatures. The final product is a pasta masterpiece achievable through extraordinary advances in technology and 3D printing.

I conducted an email interview with Jacqueline Delgado of Blu1877. Below are my questions:

* How long has Blu1877 been working on 3D pasta printing?

It’s been in development for about five years. Initially, it was an experiment in innovation to see if it was indeed possible. In partnership with TNO, a Dutch engineering and design firm with expertise in 3D printing, the first prototypes were developed.

* How are pasta shapes created?

We use a CAD program to build them. As long as the shape will stand up during printing, it can be done. The main benefit of 3D printed pasta is that it unlocks the doors of creativity, artistry, and personalization. While pasta remains an excellent carrier and platform for flavor exploration, it’s been made the same way – by hand and extrusion – for hundreds of years. 3D printing allows for shapes that are limited only by the imagination. Now, a whole new field of unique visual, textural, flavor, and ingredient combinations are possible through this technology.

* Describe a 3D printed pasta design and how it differs from what is available commercially.

Visually speaking, 3D pasta shapes will almost always be much more striking, artful and different. That’s the whole point! Let’s take the vortipa shape. (A star-shaped pasta with multiple points that begins with one large star and becomes narrower and taller with each additional star pasta layer.) It acts and tastes like fresh pasta acts and tastes in the mouth. In the case of the vortipa, it’s a thicker-textured cut and you can taste the wheat. It also has the signature al dente resilience of quality pasta.

* Can you describe the dough used in the 3D printing process?

The dough used to make 3D pasta is made of the same ingredients – durum wheat semolina and water. With that said, we are not limited to a single formulation. As with traditional pasta products, other ingredients can be added to the dough to add color and flavor.

* What designs have you considered?

* What designs have you considered?

In May 2017, Barilla concluded the Smart Pasta design competition with Desall, a leading design and open innovation platform, which attracted 680 designers from 124 countries to enter their concepts. In all, 1,200 projects were submitted. The first award went to Andreas Anedda of Italy for his turbine design. Second place went to Germany’s Cornelius Comanns for his water lily concept. Third place was awarded to Marco Ferrario hailing from Italy for his pignabarilla pasta.

* How does Blu1877 foresee using 3D pasta printing in the future?

We see the BluRhapsody project first finding a home with exclusive, high-end customers and chefs looking for a one-of-a-kind culinary expression. We would work with them to create their custom shape and deliver it printed anywhere in the world. As momentum and desire for this type of product builds, it’s possible that the market and availability would expand as well to reach other chefs and their interested clientele. BluRhapsody will continue exploring commercialization prospects for 3D pasta.

* Will the machines be available in the US?

In the short term, no. Our main focus will be on providing personalized top-end product service.

BluRhapsody will be featured at CAFÉ’s Deans and Directors Retreat during an Innovation Panel. Please click here for an agenda and retreat details.

Pictures courtesy of Blu1877

For more information on BluRhapsody please visit:

https://www.instagram.com/blurhapsody_food/?hl=en

https://blurhapsody.it/

https://www.facebook.com/BluRhapsodyFood/