Upcycling Food Waste by Creating Coproducts

01 May 2023Reimagining the end of the food cycle as the beginning.

By Lisa Parrish, GMC Editor

Feedback & comments: This email address is being protected from spambots. You need JavaScript enabled to view it.

If you recycle an aluminum Coke can, perhaps the next time you buy a Pepsi, the second soda can might have a portion of the original Coke can. Recycling takes what is left after the product is consumed and reuses it. But, what about how the product is made and the waste created from production? Where do those leftovers go?

Let’s move into the food system arena and discuss waste created not only after using an ingredient or making an application but also in the making of the ingredient or application. Food upcycling tackles that specific challenge; taking unwanted waste or ingredients that otherwise would not have gone into human consumption and transforming it into high-quality new materials or products with environmental benefits. In other words, creating coproducts from waste, not byproducts.

Beer making is an upcycling case study. It takes around two pounds of grain to make one gallon of beer leaving about 1.7 pounds of nutritionally dense spent byproduct. A small brewery typically generates between 500 and 1,000 pounds of spent grain in the process of brewing about 20 kegs of beer. That adds up to roughly two tons of spent grain per week. Traditionally, the leftovers filled landfills or compost piles, or if the brewer had a relationship with a farmer, a portion of the waste went to animal feed.

Beer making is an upcycling case study. It takes around two pounds of grain to make one gallon of beer leaving about 1.7 pounds of nutritionally dense spent byproduct. A small brewery typically generates between 500 and 1,000 pounds of spent grain in the process of brewing about 20 kegs of beer. That adds up to roughly two tons of spent grain per week. Traditionally, the leftovers filled landfills or compost piles, or if the brewer had a relationship with a farmer, a portion of the waste went to animal feed.

It took an underage homebrewer making bread in a fraternity kitchen to begin the upcycling food revolution. While attending UCLA, Dan Kurzrock, founder and CEO of Upcycled Food Inc., decided to use the spent grain from his homebrew beer and transform it into flour that he then used to bake bread. Kurzrock sold the bread to his friends to make money for more homebrewing supplies. And with that, the grain of an idea sprouted for Kurzrock: edible upcycling.

Upcycling food rescues overlooked and undervalued foods and creatively reuses them to produce a high-value product. Today, ReGrained, a company Kurzrock co-founded with his college roommate, harvests spent brewery grain to use in its Super Grain+® flour which makes baking mixes, pasta, puffs, snack bars, and more in addition to selling the flour to food manufacturers.

Kurzrock explained upcycling and its positive environmental impacts in a TED talk, “We elevate food (that would be wasted) to higher uses.”

The culinary field has a strong tradition of retrieving all the value from ingredients. He offered nose-to-tail cooking as an example. “Chefs make stocks with bones and vegetable broths with leftover veggies. There is a rich human history of using everything,” he said. “Chefs understand what they put into their food has purpose and impact.”

He also cited the example of whey, a byproduct of making cheese. Cheesemakers used to throw out the whey until it was realized there was a market for the dehydrated, high-protein substance and began selling it to the supplement and nutrition industry. “Now, sometimes cheese is the byproduct of whey production,” said Kurzrock.

Upcycling not only addresses reusing food byproducts from manufacturing, but it also shines a light on the wasted resources that occur in making or growing the ingredient. Kurzrock cited the example of farming broccoli. “People are only eating the top 25 or 30 percent of the plant,” he said. In broccoli farming, nearly 75 percent of the stalks and leaves can be left in the field after harvesting.

Upcycling not only addresses reusing food byproducts from manufacturing, but it also shines a light on the wasted resources that occur in making or growing the ingredient. Kurzrock cited the example of farming broccoli. “People are only eating the top 25 or 30 percent of the plant,” he said. In broccoli farming, nearly 75 percent of the stalks and leaves can be left in the field after harvesting.

“We are wasting nearly a third of all food we are producing globally,” he said. “This represents about eight percent of human-caused greenhouse gas emissions. This is billions of dollars in lost revenue opportunity.”

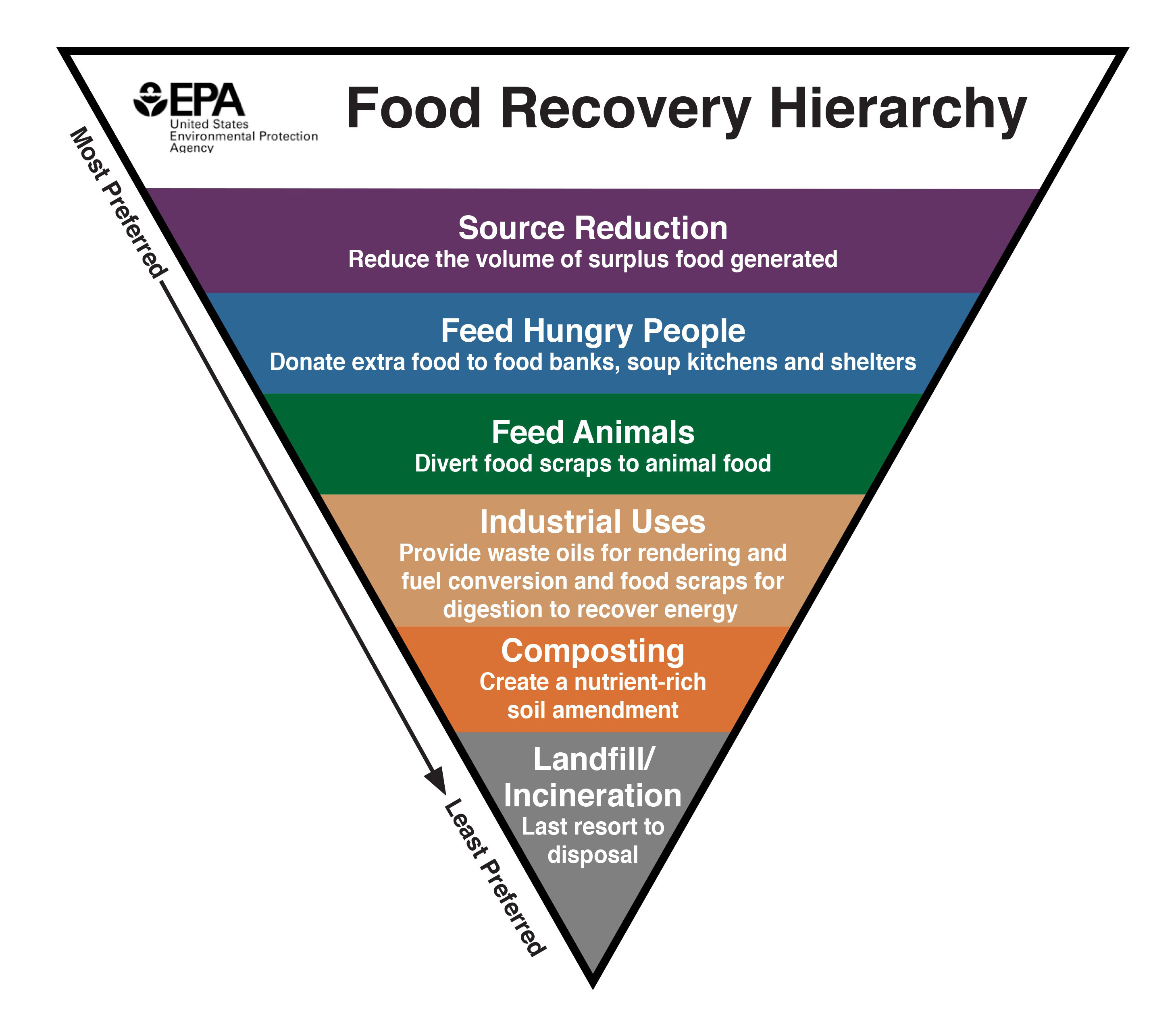

Upcycling looks to change food waste by looking at the planet’s resources and trying to get everything to the highest possible use. Using the Food Recovery Hierarchy, Kurzrock and his companies look to produce more food by reducing surplus food and byproducts.

An example of a new upcycled product just coming to market is a plant-based meat derived from the cashew fruit. For every cashew nut grown, there is a fruit attached to it called the cashew apple. In Brazil, 2.2 million tons of cashew apples are thrown out every year. However, a Hawaiian company, Caju Love, determined that the fruit makes a flavorful and nutritious meat alternative and is now selling it online and joining the upcycling revolution.

An example of a new upcycled product just coming to market is a plant-based meat derived from the cashew fruit. For every cashew nut grown, there is a fruit attached to it called the cashew apple. In Brazil, 2.2 million tons of cashew apples are thrown out every year. However, a Hawaiian company, Caju Love, determined that the fruit makes a flavorful and nutritious meat alternative and is now selling it online and joining the upcycling revolution.

The mission of ReGrained is, “To better align the food we eat with the planet and people we love.” Kurzrock and his colleagues are at the nexus of bringing together people, the planet and profit. Or as he said, “This is the nexus of where doing good and doing well are the same thing.”

To learn more about Dan Kurzrock, listen to the latest CAFÉ Talks podcast “Rethinking Waste” featuring the entrepreneur.

Additionally, Kurzrock will present a featured keynote address at CAFÉ’s Leadership Conference on June 22.